Capgemini’s study entitled “Scaling AI in manufacturing operations: A practitioners’ perspective” analyzes the implementation of AI in the 75 largest organizations in the world in four industrial sectors: Industrial production, Automotive, Consumer products and Aeronautics & Defense.

More than half of European manufacturers are setting up AI use cases, with Germany coming out on top with a rate of 69%, compared to 28% for the United States and 11% for China. This is demonstrated by a new study published by the Capgemini Research Institute, which notes the advance of the European market in terms of the integration of artificial intelligence into industrial operations.

51% of the world’s largest industrial groups located in Europe use at least one case of AI use. The analysis of 22 use cases reveals that intelligent maintenance, product quality control and demand planning are the three main uses that allow manufacturers to embark on the adventure of AI.

The study shows that AI offers significant potential for manufacturers in terms of reducing operating costs, increasing productivity and improving quality. According to this study, the major global manufacturers based in Germany (69%), France (47%) and the United Kingdom (33%) are the leaders in the deployment of AI in their activities of production.

The main conclusions of the study

AI is used and makes the difference at all stages of the value chain : Pioneer organizations are using AI in their production activities to reap significant benefits. This is the case, for example, of the agrifood company Danone, which has managed to reduce forecast errors by 20% and loss of sales by 30% thanks to machine learning to predict the variability of demand.

At the same time, tire manufacturer Bridgestone implemented a new assembly system based on automated quality control, which has resulted in more than 15% improvement in product compliance.

Manufacturers tend to focus on the top three use cases to get started in the AI adventure

According to the report, manufacturers embark on the adventure of AI by focusing on three use cases (out of the 22 identified in the study), which are an ideal starting point because they combine several characteristics , in particular: a rapid and significant financial return, a relatively easy implementation, the availability of data and packaged solutions.

Executives interviewed by Capgemini noted that product quality control, intelligent maintenance and demand planning are the areas where AI can be most easily implemented and provide the best return on investment. For example, General Motors (GM) has experimented with a system to detect signs of robotic failure before it occurs. GM has avoided the costs of unplanned outages of up to $ 20,000 per minute of downtime.

While there is consensus on the most appropriate use cases to start using AI, the study also highlights the challenge of scaling up beyond first deployments and then exploitation. the potential of AI beyond these first use cases.

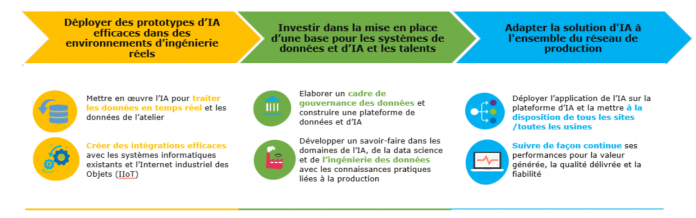

At the end of the study, recommendations for integrating AI into production activities (see the figure below):

Source : Capgemini